Electrical Load Calculation in Building Design: Step-by-Step Guide

Introduction

Electrical Load Calculation in building design is a critical process to ensure the safety, reliability, and efficiency of electrical systems. Whether it’s for residential, commercial, or industrial purposes, accurate load calculations are essential to meet the unique power requirements of each space. In this article, we will provide a comprehensive step-by-step guide for Electrical Load Calculation in Building Design, helping you navigate this crucial aspect of construction.

There are two main stages of load calculations:

- Preliminary Load Calculations: Preliminary load calculations are performed at the early stages of the design process, often during the conceptual or schematic design phase. They provide a rough estimate of the loads a building is likely to experience based on basic design parameters and assumptions. Units of Loads will be in (W/ft2) watts per square foot or (VA/ft2) volt-amperes per square foot. These are easy and fast calculations and help in making high-level decisions such as requesting power supply from the utility company and estimating initial project budgetary requirements.

- Final Load Calculations: Final load calculations are performed at a

more advanced stage of the design process when the building’s design and

specifications are well-defined. Units of Loads will be in KW (kilo-watt), KVA

(kilo-volt-ampere), or HP (horsepower). These calculations ensure that the

equipment and materials are sufficient to meet current, prospective, and future

load requirements.

General Process to Calculate Electrical Load of Buildings

Following are the key steps of electrical load calculation in building design:

Step 1: Gather Information

Start by collecting all the necessary information about the area or building, including:

- The type of area (residential, commercial, or industrial).

- The total floor area or square footage of the building.

- The type of electrical appliances, equipment, and lighting used.

- The power ratings (in watts or kilowatts) of all electrical devices and equipment.

- The operating hours and duty cycles of equipment (if applicable)

- The local electrical code requirements and standards.

Step 2: Identify Electrical Loads

Categorize the electrical loads into different categories based on their purpose, such as lighting, HVAC (heating, ventilation, and air conditioning), appliances, machinery, and any special equipment.

Step 3: Calculate the Load for Each Category

For each load category, calculate the load by multiplying the quantity of devices or equipment by their respective power ratings (in watts or kilowatts). If equipment operates intermittently, consider the duty cycle or usage hours.

- Example for lighting: Total wattage of all light fixtures × Number of hours lights are on per day.

Step 4: Sum Up the Loads

Sum up the loads for each category to get the total electrical load for the area or building. This will be in watts or kilowatts.

Step 5: Consider Diversity Factors

In commercial and industrial settings, you might apply diversity factors to account for the fact that not all electrical equipment operates at full load simultaneously. This can reduce the peak demand on the electrical system.

Step 6: Convert to Amperage (Optional)

If you need to size electrical conductors and circuit protection, you may need to convert the total load to amperage. Use the formula: Amperage (A) = Power (W or kW) / Voltage (V). Standard residential voltage in many countries is 120V or 240V, while commercial and industrial facilities may use different voltages.

Step 7: Account for Future Growth

It’s essential to consider future growth and expansion when calculating the electrical load to avoid having to upgrade the electrical system frequently.

Step 8: Comply with Codes and Regulations

Ensure that your calculations comply with local electrical codes and regulations. Different regions may have specific requirements for load calculations, safety, and electrical system design.

Also read: Essential Codes and Standards for Electrical Load Calculation

Example

Here’s an example of a Preliminary Electrical Load Calculation using the Space-by-space Method while considering diversity and demand factors, as well as adhering to local electrical codes and standards:

Scenario:

You are designing the electrical system for a Small Office Building with various spaces and different electrical needs.

Information:

- Total Area: The office building has a total floor area of 10,000 square feet.

- Occupancy Type: The building has a mix of office spaces, conference rooms, a kitchenette, and restrooms.

- Code Compliance: You must adhere to local electrical codes and standards that specify demand factors for various space types.

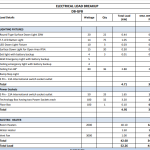

Preliminary Electrical Load Calculation

- Lighting Load: Consider the square footage and occupancy type of each area. Refer to local codes for demand factors. (See Lighting Load Density values in different codes)

- Office Spaces (6,000 sq.ft ):

- Lighting Load = Area x Lighting Load Density x Demand Factor

- Lighting Load = 6,000 sq.ft x 0.56 watt/sq.ft x 0.75 (demand factor) = 2,520 watts or 2.5 kW

- Conference Rooms (1,000 sq.ft ):

- Lighting Load = 1,000 sq.ft x 0.88 watts/sq.ft x 0.8 (demand factor) = 704 watts or 0.704 kW

- Kitchenette (500 sq.ft ):

- Lighting Load = 500 sq.ft x 1.19 watts/sq.ft x 0.85 (demand factor) = 505.75 watts or 0.506 kW

- Restrooms (200 sq.ft ):

- Lighting Load = 200 sq.ft x 0.74 watts/sq.ft x 0.7 (demand factor) = 103.6 watts or 0.103 kW

- Office Spaces (6,000 sq.ft ):

- Receptacle Load: Estimate the receptacle load density for each space based on code requirements and apply demand factors. Refer to local codes for receptacle load values.

- Office Spaces (6,000 sq.ft ):

- Receptacle Load = Area x Receptacle Load Density x Demand Factor

- Receptacle Load = 6,000 sq.ft x 1 watts/sq.ft x 0.7 (demand factor) = 4,200 watts or 4.2 kW

- Conference Rooms (1,000 sq.ft ):

- Receptacle Load = 1,000 sq.ft x 1.5 watts/sq.ft x 0.8 (demand factor) = 1,200 watts or 1.2 kW

- Kitchenette (500 sq.ft ):

- Receptacle Load = 500 sq.ft x 2 watts/sq.ft x 1.0 (demand factor) = 1,000 watts or 1 kW

- (Demand factor for kitchen equipment other than dwelling units: 100% NEC Table 220.56)

- Receptacle Load = 500 sq.ft x 2 watts/sq.ft x 1.0 (demand factor) = 1,000 watts or 1 kW

- Restrooms (200 sq.ft ):

- Receptacle Load = 200 sq.ft x 0.5 watts/sq.ft x 0.6 (demand factor) = 60 watts or 0.06 kW

- Office Spaces (6,000 sq.ft ):

- Total Preliminary Electrical Load: Add up the lighting and receptacle loads for all areas.

- Total Preliminary Load = (Lighting Load + Receptacle Load) for all areas

- Total Preliminary Load = (2.5kW + 0.704kW + 0.506kW + 0.103kW) + (4.2kW + 1.2kW + 1kW + 0.06kW) = 10.27 kW

Conclusion

In conclusion, this comprehensive guide has provided an extensive exploration of electrical load calculations across residential, commercial, and industrial settings. It has delved into the fundamental principles, critical factors, and industry standards that underpin accurate load assessments. Whether you’re an electrician, engineer, or simply seeking a deeper understanding of electrical systems, this guide equips you with the knowledge and tools needed to navigate the complexities of electrical load calculations successfully. Empowered with this expertise, you can design, install, and maintain electrical systems with precision, efficiency, and safety in mind, ensuring the reliable and sustainable operation of your projects.

A dedicated Electrical Engineer with expertise in ISO auditing and a strong passion for sharing insights into the electrifying world of design. With over 5 years of diverse experience, I’ve powered through projects ranging from the manufacturing industry to building construction. My skillset extends to automation building design, where my meticulous electrical drawings ensure precision and attention to detail.